We introduce our production process. Please, put your mouse on process which you want to know more details.

We introduce our production process. Please, put your mouse on process which you want to know more details.

Sub Assembly

Processing

Finishing /

Inspection

Shot Blasted

Shaking out of Mold

Pouring

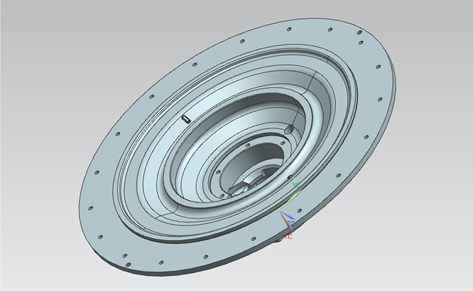

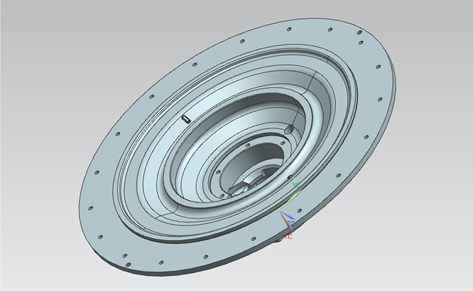

Design

Propose suitable casting design to satisfy customers’ requirement.

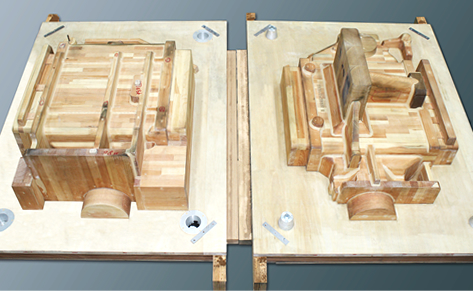

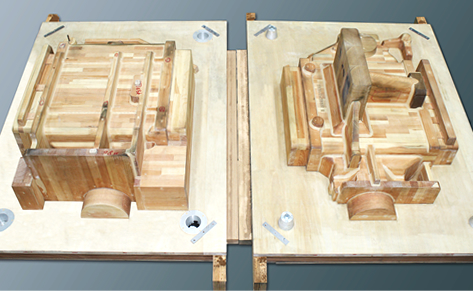

Manufacture Wooden Pattern

By using 3DCAD, we design the accurate chemical wooden pattern.

Molding

We use original Robot Mixer to manufacture Sand Mold. The Mixer can control sand, shaping process and manufacturing time from the information designed on Wooden pattern.

Parting

After Sand Mold hardens, Sand Mold and Wooden pattern divided automatically by using Automatic Parting Machine.

Mold Coating

Fire resistance coating.

Mold Assembly

Coated Sand Molds, top and drag parts are jointed to one mold.

Pouring

Melting iron and its chemical composition is controlled with GID original design and pouring into the Mold.

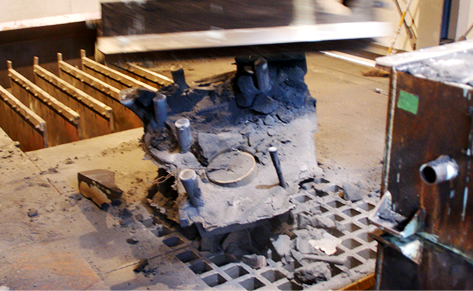

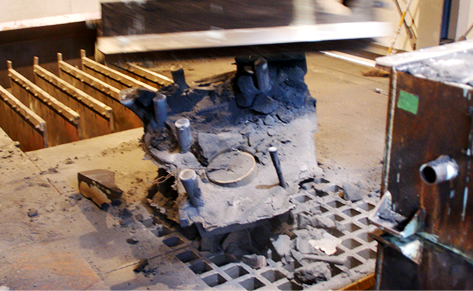

Shaking out of Mold

After melting iron in the Mold become hard and cooling down, the top and drag molds are disjointed.

Shot Blasted

Shot blasted to remove sand on product surface.

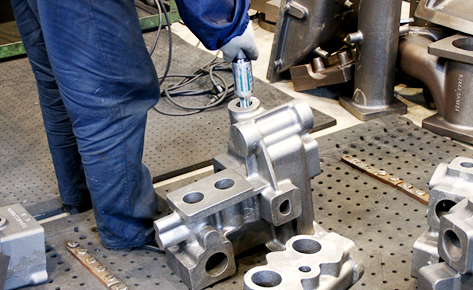

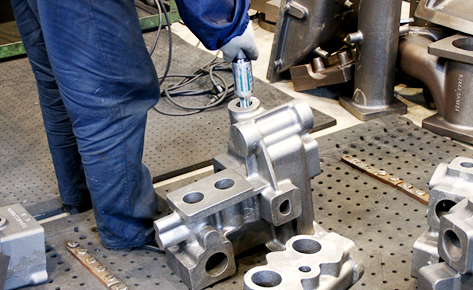

Finishing / Inspection

Inspectors check the quality of finishing product before shipment

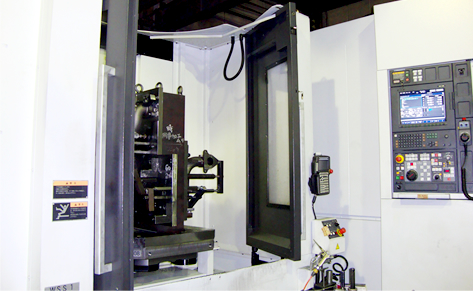

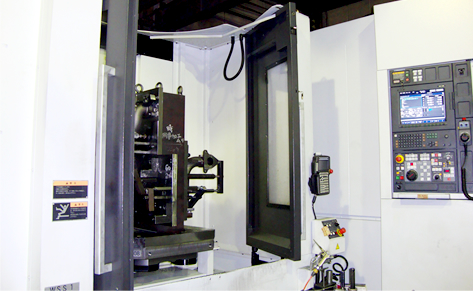

Processing

GID can processing such as drilling.

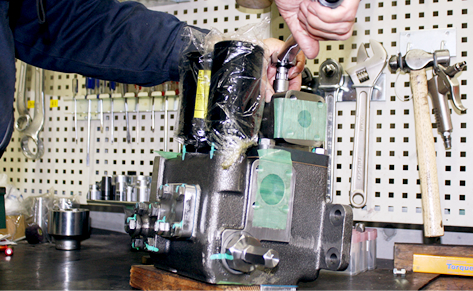

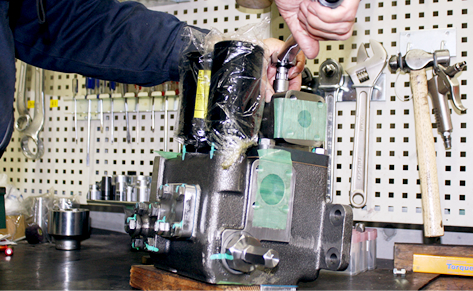

Sub Assembly

According to customers’ requirement, we have an option to subassembly before shipment.